INSTALLATION MEASUREMENT SYSTEM

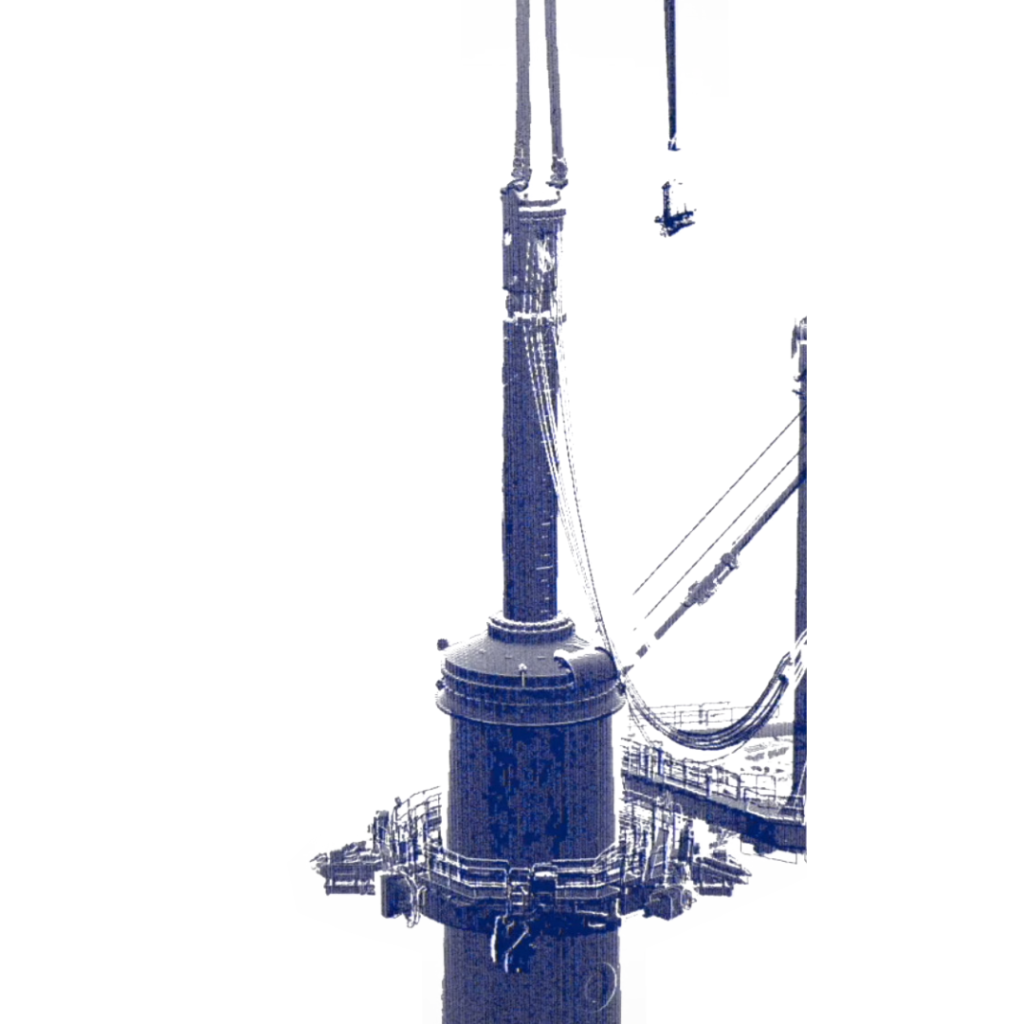

INTRODUCING THE PLIANT OFFSHORE IMS

structure such as a monopile during installation and is specially designed for continuous measurements during piling.

features

Installation Measurement System measures inclination and position while piling. Seamless merging of online and offline functionality in one program. Being able to quickly inspect a scan in Single Measurement Inspection View gives insight how to improve processing whilst online. Batch Analysis and Reprocessing can help test new settings/ideas for a robust test before starting the next pile.

01

Up to 0.05° accurate

02

Supports multiple ship configurations

03

Less errors and failures

04

The IMS has proven to save approximately 0.5 hours per monopile

05

Fully motion compensated

06

Reliable in all weather conditions

07

Robust and proven technology

“IMS is unquestionably a revolutionary system that contains very powerful tools and features.

The reliability of its computations and algorithms have proven to be robust during many hours of development, testing, and real-world operation.”

Jon Southwell – Van Oord

information

Proven concept

IMS has been proven its worth already at the Walney and Arkona wind farms. Also, the IMS is used at the Seamade, Deutsche Bucht and East Anglia One projects. With IMS the installation has proven to be faster and more accurate than any conventional method.

Cost efficient

The IMS has proven to save ±0.5 hour per monopile installation since piling doesn’t have to be interrupted. Besides that, it has proven to save significantly on cost for öxing errors

Survey

All 3D measurements can be stored, analyzed and played back for offline analysis, survey and quality control of the used monopiles and the installation process itself. This information is very valuable for reporting to the client.

Accurate

The Pliant DAMS is built using only high-grade offshore-proof materials to ensure durability. The device has an internal climate controlled environment, sealed in an airtight stainless steel box for maximum robustness in demanding offshore conditions.

IMS for as built

IMS can also be used for detailed reconstruction of as built dimentions. Up to an accuracy of 0,5mm.

Less errors and failure

Not only does the system allow you to complete monopile installation faster, since you don’t need to stop piling for an accurate measurement, but by using IMS you will have less chance of installation errors of the monopiles because the system measures position, orientation, inclination and height of the monopile and compares this in real time with the expected design parameters.The IMS is able to deal with deformed piles. Dents, misalignment and piles will no longer result in deviations of the angle. Again this means saving valuable time.

Robust and proven technology

The IMS is successfully used for multiple installation projects on various vessels. It has proven to be robust and very suitable for harsh offshore conditions while maintaining accuracy.

Faster installation

The IMS can yield higher up-time; during the installation process piling does not have to be suspended for conventional contact measurements. The non-destructive contact-free measurements allow continuous control during installation and piling which can greatly improve the overall time required for installation

inclination measurement system by pliant offshore

ims compact

IMS is also available in a compact version for easy re-location on the vessel. The compact version exists of a separate measurement unit (verwijs naar de render) an a separate power distribution box with connectors in between.

With the generic interface plate the compact IMS can easily be bolted to any available mounting position on the vessel.

ROBUST AND PROVEN TECHNOLOLGY

“IMS has consistently proven itself to be a reliable and accurate system throughout the whole piling process, offering a clear advantages over other methods and completely negates the need for the spirit level.

IMS provides a level of automation not provided by any other system and removes the potential for user error in determining inclination and direction, reducing the change of an MP being installed outside specification.”

Jon Southwell – Van Oord

WANT TO KNOW MORE ABOUT US?

Find out more about our team and the skills we have in measurement technical offshore solutions. Or visit us at our headquarters in Breda, the Netherlands.

PLAN DEMONSTRATION

Our team is always available for additional information or a free demonstration. Please feel free to send us an email with the form below and we will get back to you as soon as we can. You can also call us at (+31)76 581 6588.